| Sign In | Join Free | My insurersguide.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My insurersguide.com |

|

Brand Name : FOTMA

Model Number : CuW Alloy Plate

Certification : ISO9001:2008

Place of Origin : P.R. China

MOQ : 1 pcs

Price : Negotiable

Payment Terms : T/T, L/C, Western Union, PayPal

Supply Ability : 10000pcs/month

Delivery Time : 20-25 days after deposit

Packaging Details : Paper cartons or plywood boxes

W Content : 50% to 90%

Thickness : 0.1mm - 1.0mm

Length : 50 - 400mm

Width : 50 - 400mm

Surface : Rolled

Tolerance : +/-0.05mm

ANSI Standard Tungsten Copper Alloy Sheets Infiltrated 0.1mm to 1.0mm for EDM Machine

Tungsten copper (copper tungsten, CuW, or WCu) alloy is a pseudo-alloy of tungsten and copper. As copper and tungsten are not mutually soluble, the material is composed of distinct particles of one metal dispersed in a matrix of the other one. The microstructure is therefore rather a metal matrix composite than a true alloy.

Tungsten copper alloy combines the properties of both metals, resulting in a material that is heat-resistant, ablation-resistant, highly thermally and electrically conductive, and easy to machine.

Parts are made from the tungsten copper alloy by pressing the tungsten particles into a desired shape, sintering the compacted part, and then infiltrating with molten copper. Sheets, rods and bars of tungsten copper alloy are available as well.

Applicatioins of Tungsten Copper Sheets:

Tungsten copper alloy sheets are used worldwide for EDM (Electrical Discharge Machining) and ECM (Electrochemical Machining) electrodes. All material is manufactured by the press, sinter, and infiltrate process. Virgin tungsten powders are used, resulting in a consistent homogeneous material giving high and even burning rates. Tungsten copper is used in plunger/sinker applications where intricate definition is required, especially in tungsten carbide.

Advantages of Copper Tungsten Sheets:

Maturity press- sinter- infiltration process without any porosity issue.

high electrical conductivity get rapid cutting speed

1. Better heat resistant;

2. Better ablate-resistant;

3. High intensity

4. High density;

5. Excellent thermal and electrical conductivity;

6. Easyto be machined.

Specifications of Copper Tungsten Sheets:

| Type Dimension(mm) Note: | |||

| W-Cu copper | Length(mm) | Width(mm) | Height(mm) |

| W70 | 100-600 | 10-300 | 2-200 |

| W75 | 100-600 | 10-300 | 2-200 |

| W80 | 100-600 | 10-300 | 2-200 |

| W85 | 100-600 | 10-300 | 2-200 |

| W90 | 100-600 | 10-300 | 2-200 |

Size Chart of WCu Sheets:

| Thickness | Width | Length |

| 0.10-0.15 | 300 | 1000 |

| 0.15-0.20 | 400 | 1000 |

| 0.20-0.30 | 600 | 1500 |

| 0.30-0.50 | 600 | 2000 |

| 0.50-1.0 | 600 | 2000 |

| 1.0-2.0 | 600 | 1500 |

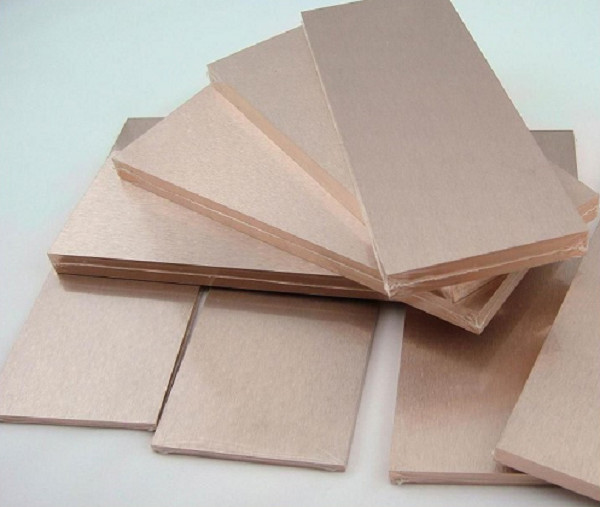

Picture show:

|

|

ANSI Infiltrated Copper Tungsten Sheets 0.1mm - 1.0mm For EDM Machine Images |